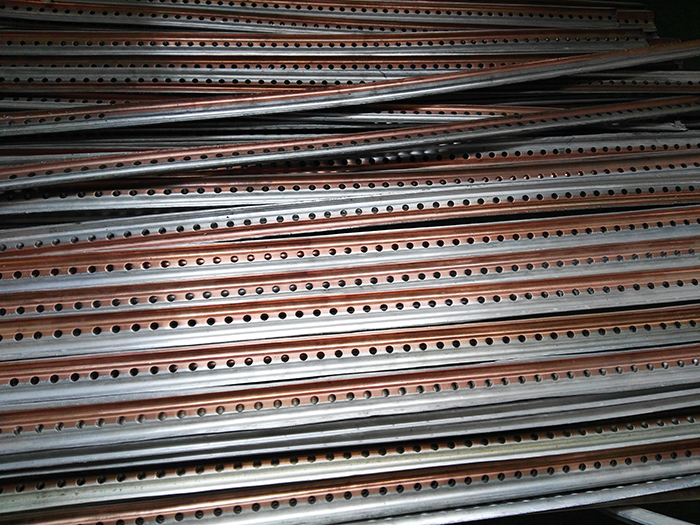

Copper Aluminum Trans-Busbar

Author:Frank Time:2023-05-05

Single - Double – Sided Copper - Aluminum Composite Transition Sheet BusbarWith the rapid development of lithium battery automobile industry, the problem of PACK connection of lithium battery is becoming more and more prominent. Many buses to the vehicle battery pack thousands of groups, of monomer battery anode material of aluminum foil and copper foil, is how to realize the lithium battery pack is safe, reliable, light weight, simple string, and the connection is the bottleneck restricting the development of lithium battery car technology.

Signi Aluminium Company has developed two kinds of copper - aluminum composite materials connected by independent innovation.Copper - aluminum composite base column material and copper - aluminum composite transition film.Column base material, and 10 mm aluminium plate with 3 mm copper composite made of copper aluminum composite column material, complete copper cathode copper set associative, and aluminum and aluminum plate, forming two electrodes are exposed aluminum battery pack can be done with the normal laser welding process connection; Connecting sheet material: a copper strip with 10mm in the middle of the aluminum plate, copper strip through copper rivets and internal copper set, and the aluminum plates on both sides of the aluminum plate are connected in parallel with each other.

Technical parameters:

Composite strength: = 12N/mm;

Compound rate: 100%;

Shear strength: >= 35Mpa;

Tensile strength: 90-130mpa;

Extension rate: <= 35%;

Dc resistivity: < = 0.0245 Ω. Mm2/m;

Product features :

high conductivity, high mechanical strength, good reliability, low density and cost saving, high composite strength, metallurgical combination of copper and aluminum, no contact resistance between copper and aluminum, stable and reliable quality.

Product size : customized according to user demand.

Technical parameters : composite strength: greater than 100MPa;

Specification:

| Weight Display in Common Specification | ||||||||

|---|---|---|---|---|---|---|---|---|

| Specification a*b(mm) | 3*30 | 3*40 | 3*50 | |||||

| Weight/meter(kg) | 0.31 | 0.42 | 0.53 | |||||

| Specification a*b(mm) | 4*40 | 4*50 | 4*60 | 4*80 | ||||

| Weight/meter(kg) | 0.56 | 0.7 | 0.84 | 1.12 | ||||

| Specification a*b(mm) | 5*40 | 5*50 | 5*60 | 5*80 | ||||

| Weight/meter(kg) | 0.7 | 0.875 | 1.05 | 1.4 | ||||

| Specification a*b(mm) | 6.4 | 6*50 | 6*60 | 6*80 | 6*100 | |||

| Weight/meter(kg) | 0.84 | 1.05 | 1.26 | 1.68 | 2.1 | |||

| Specification a*b(mm) | 8*50 | 8*60 | 8*80 | 8*100 | 8*120 | 8*200 | ||

| Weight/meter(kg) | 1.4 | 1.68 | 2.24 | 2.8 | 3.36 | 5.6 | ||

| Specification a*b(mm) | 10*60 | 10*80 | 10*100 | 10*120 | 10*150 | 10*200 | 10*250 | 10*300 |

| Weight/meter(kg) | 2.1 | 2.8 | 3.5 | 4.2 | 5.25 | 7 | 8.75 | 10.5 |

Characteristics

1) Proportion of Copper/Aluminum is 2:8 and the proportion could be adjusted by customer's demand.

2) Single and double side copper clading are available.

3) Consistency of thickness is stable and very suitable for mass stampling production.

4) Resistance to corrosion and high temperature (500degree c without separation).

5) With good stability, excellent deep drawability and tensile properties, it can even bear 90°bend without separation.

6) With an electrical conductivity of 98% or more, it can completely replace pure copper by saving cost64% under same volume.

7) The dimension can be produce as requested.

Signi Aluminium Co., LTD. has independently developed and produced the material for the production of copper and aluminum, which is widely used in the transformer, reactor and other electrical industry, effectively replacing the traditional flash welding and brazing process.