Aluminum Copper Bimetal Busbar

Author:Frank Time:2023-05-05

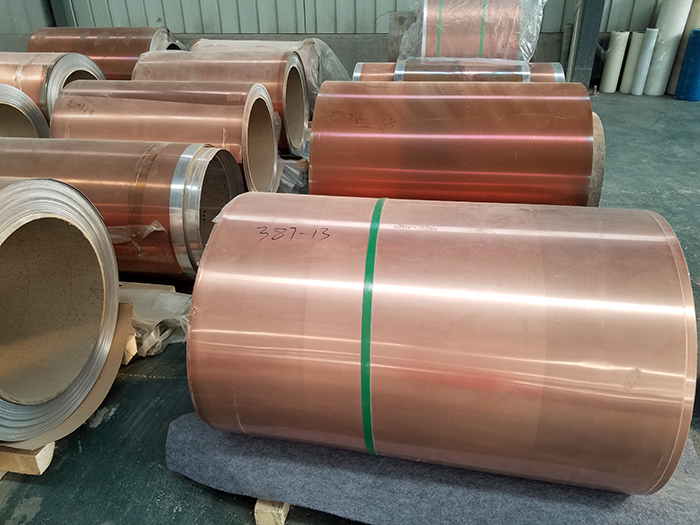

Single-Double-Sided Copper Aluminum Composite Bimetal Sheet BusbarCopper aluminum composite is a kind of outer layer copper or aluminum composite conductive material, will have a large number of application in the electric distribution equipment, as a large current current-carrying conductor, to replace copper platoon design, as well as copper platoon of convenient processing and use.According to the principle of "skin effect", the current is concentrated in the surface of the conductor, so the copper in the inner core is not very important.The copper and aluminum composite sheet busbar is based on this principle to replace copper core copper with aluminum, which is combined with a series of complex processes to combine copper and aluminum composite conductive materials.

Copper aluminum bimetallic busbar has the characteristics of copper conductivity and low density of aluminum at the same time. Copper aluminum bimetallic busbar is known as the third generation of new conductor after copper and aluminum in Europe and America. It is widely used in automation, metallurgy, high and low voltage electrical appliances, construction industry, metallurgy industry and other industries

The copper aluminum bimetallic busbar makes full use of the advantages of strong corrosion resistance, small contact resistance and high load, and the advantages of light weight and low cost.Give full play to the advantages of the two materials of copper and aluminum, proper overcomes the shortcomings of their own at the same time, have a large number of used in the industries of electric power distribution equipment, at the same time also can help customers to save cost of 40% - 50% of the conductor.

Product size: the thickness is 3.0mm~ 15.0mm, and the width is less than 1000mm.

Product features: it can be divided into various specifications according to the user's needs, and can meet the large current and the power supply demand of the large section. High composite strength can be used for bending, drilling, bending, electroplating tin and other deep processing, can replace pure copper sheet busbar .Due to the effect of skin effect, the actual conductivity of copper and aluminum composites is higher than that of copper and aluminum in parallel.

Specification:

| Weight Display in Common Specification | ||||||||

|---|---|---|---|---|---|---|---|---|

| Specification a*b(mm) | 3*30 | 3*40 | 3*50 | |||||

| Weight/meter(kg) | 0.31 | 0.42 | 0.53 | |||||

| Specification a*b(mm) | 4*40 | 4*50 | 4*60 | 4*80 | ||||

| Weight/meter(kg) | 0.56 | 0.7 | 0.84 | 1.12 | ||||

| Specification a*b(mm) | 5*40 | 5*50 | 5*60 | 5*80 | ||||

| Weight/meter(kg) | 0.7 | 0.875 | 1.05 | 1.4 | ||||

| Specification a*b(mm) | 6.4 | 6*50 | 6*60 | 6*80 | 6*100 | |||

| Weight/meter(kg) | 0.84 | 1.05 | 1.26 | 1.68 | 2.1 | |||

| Specification a*b(mm) | 8*50 | 8*60 | 8*80 | 8*100 | 8*120 | 8*200 | ||

| Weight/meter(kg) | 1.4 | 1.68 | 2.24 | 2.8 | 3.36 | 5.6 | ||

| Specification a*b(mm) | 10*60 | 10*80 | 10*100 | 10*120 | 10*150 | 10*200 | 10*250 | 10*300 |

| Weight/meter(kg) | 2.1 | 2.8 | 3.5 | 4.2 | 5.25 | 7 | 8.75 | 10.5 |

Characteristics

1) Proportion of Copper/Aluminum is 2:8 and the proportion could be adjusted by customer's demand.

2) Single and double side copper clading are available.

3) Consistency of thickness is stable and very suitable for mass stampling production.

4) Resistance to corrosion and high temperature (500degree c without separation).

5) With good stability, excellent deep drawability and tensile properties, it can even bear 90°bend without separation.

6) With an electrical conductivity of 98% or more, it can completely replace pure copper by saving cost64% under same volume.

7) The dimension can be produce as requested.

This product by China non-ferrous metal research institute, chinalco LuoTong institute, henan university of science and technology institute of materials research, and other units of batch test, the conductivity of the measured were superior to the current domestic similar products.Chemical composition is stable.The raw materials are the first-class products in China, the products are large quantity and the production quality is stable.The company owns more than 50 sets of special equipment for composite materials, effectively guaranteeing the product quality.The products are well received by the majority of users.

The main application range of copper and aluminum composite sheet busbar is: high frequency, medium frequency heating equipment, composite battery connection, railway track and other conductor, crane sliding contact line;Busbar system, bus-flow high pressure, low pressure bus trough;Switch cabinet (low pressure, medium pressure, high pressure), switchboard, electric control box.

Double-sided copper and aluminum composite sheet busbar is suitable for the use of busbar and switch cabinet.Because copper is much more expensive than aluminum, the obvious role of copper aluminum composite sheet busbar is to lower the cost of materials for enterprises.The same copper clad aluminum sheet busbar, whose price is about 50% of the traditional pure copper row.In the premise of guaranteeing the quality, it can generate a good profit for the enterprise.