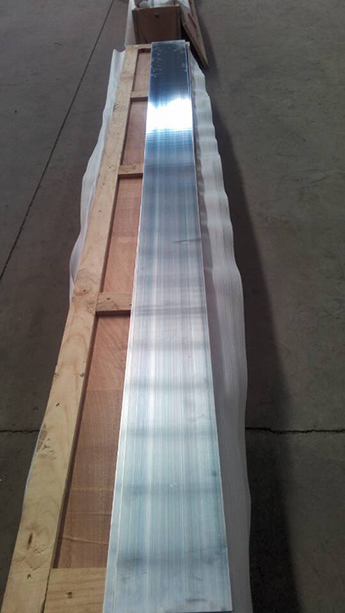

1350 Aluminium Flat Bus Bar

Author:Frank Time:2023-06-14

Pure aluminum has a conductivity of about 65 percent of the International Annealed Copper Standard (lACS). Aluminum can be produced 99.99 percent pure; however, this purity is costly to achieve and the mechanical properties are low.

Other aluminum alloys may be used for bus conductors. However, they should be used with care since conductivity and mechanical properties can be greatly affected by small amounts of alloying elements.Alloys and Tempers

Aluminum 1350 is a commercial high-purity aluminum with 61 percent conductivity. The tensile strength of each 1350 temper is determined by the amount of work given the metal during fabrication.

Most 1350 aluminum bus conductors are of -Hlli temper for extrusions, -H112 for sawed rolled plate, and -F for cast bars.

|

|

|---|

| Alloy | 1350 | Temper | O | |

|---|---|---|---|---|

| Thickness (mm) | 0.2-0.3 | 0.4-0.8 | 1.0-2.0 | 2.0-3.0 |

| Width (mm) | <100 | 100-200 | 201-500 | 500-1300 |

| Mechanical Property | ||||

| U.T.S. | Density in 20℃ | Max. Resistance in 20℃ | ||

| 60-95N/mm2 | 2.703kg/dm3 | ≤0.02825Ωmm2/m | ||

Flatwise Bending Radius

| Type of Bar | Alloy and Temper | Thickness in. | Radius min. |

|---|---|---|---|

| 1350-H11 | All | 1 * thickness | |

| Extruded | 6101-H11 |

0.250-0.750 0.751-1.000 |

1 * thickness 2 * thickness |

| 6101-T6 |

0.125-0.375 0.376-0.500 |

2 * thickness 21/2 thickness |

|

| 6101-T61 |

0.125-0.500 0.501-0.749 0.750-1.000 1.001-1.625 |

1 * thickness 2 * thickness 3 * thickness 4 * thickness |

|

| 6101-T63 |

0.125-0.375 0.376-0.500 0.501-1.000 |

1 * thickness 11/2 thickness 21/2 thickness |

|

| 6101-T64 |

0.125-0.750 0.751-1.000 |

1 * thickness 2 * thickness |

|

| 6101-T65 |

0.125-0.500 0.501-0.749 |

1 * thickness 2 * thickness |

|

| Rolled | 1350-H12 | All | 1 * thickness |

| Sawed plate | 1350-H112 | All | 1 * thickness |

Applicable to widths up through 6 inches in the T6,T61,T63 and T65 temper and to widths up through 12 inches for all other listed tempers. Bend radius for greater widths are subject to inquiry.

Chemical Composition

| Si | Fe | Cu | Mn | Mg | Cr | Zn | V+Ti | Others | Al. | |

|---|---|---|---|---|---|---|---|---|---|---|

| Individual | Total | |||||||||

| Max. 0.10 |

Max. 0.40 |

Max. 0.05 |

Max. 0.01 |

— |

Max 0.01 |

Max. 0.05 |

Max. 0.02 |

Max. 0.03 |

Max 0.10 |

Min. 99.50 |

Properties

Aluminium and Copper Specifications

Definitions :

Specific Heat: The heat required to raise the temperature of its unit by mass by 1ºC.(This is a physical property)

Density: This is it’s mass per unit volume. This is defined as mass divided by volume.

Melting Point: The point at which it changes state from a solid to a liquid.

Ultimate Tensile Strength: The maximum stress value as obtained on a stress-strain curve.

Ultimate Shearing Strength: The force that will shear the material, and act in the plane of the area at a right angle to the area subjected at such force.

Elastic Modulus: The ratio of the unit stress to the unit strain within the proportional limits of a material in tension or compression.

0.2% Tensile-proof Strength: (yield strength) The point between 60– 80% of the ultimate tensile strength of the material where a 0.2% permanent deformation will occur.

Coefficient of Expansion: This is the fractional change in length per degree of temperature change.

IACS: International Annealed Copper Standard.

Specifications :

low price aluminum bar

thickness:0.2~12.0mm

width:500~1200mm

sample: free and fast

ISO9001-2008,SGS

offer tailor-made spec.

| Square angle aluminum bar | ||||||||||

| 2mm | 2*30 | 2*40 | 2*67 | 2*70 | 2.5* 25 | |||||

| 3mm | 3*10 | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | 3*60 | 3*67 | 3*75 |

| 3*110 | ||||||||||

| 4mm | 4*10 | 4*15 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | 4*60 | 4.6*60 |

| 4.8*9.8 | ||||||||||

| 5mm | 5*15 | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | 5*100 |

| 6mm | 6*20 | 6*25 | 6*30 | 6*40 | 6*50 | 6*54 | 6*55 | 6*60 | 6*65 | 6*70 |

| 6*75 | 6*80 | 6*100 | 6*120 | 6*150 | 6*160 | |||||

| 6.3mm | 6.3*50 | 6.3*63 | 6.3*63.5 | 6.3*80 | 6.35*50.8 | 6.35*76.2 | ||||

| 7mm | 7.6*80 | 7*150 | 7*4*20*4 | |||||||

| 8mm | 8*11 | 8*30 | 8*40 | 8*50 | 8*51 | 8*60 | 8*63 | 8*63.5 | 8*65 | 8*70 |

| 8*80 | 8*90 | 8*100 | 8*120 | 8*125 | 8.8*28.6 | |||||

| 9mm | 9*170 | 9*125 | 9. 2*64 | |||||||

| 10mm | 10*20 | 10*25 | 10*30 | 10*40 | 10*45 | 10*50 | 10*60 | 10*63 | 10*65 | 10*70 |

| 10*80 | 10*90 | 10*100 | 10*110 | 10*114 | 10*120 | 10*125 | 10*140 | 10*150 | 10*160 | |

| 12mm | 12*30 | 12*40 | 12*45 | 12*50 | 12*60 | 12*70 | 12*76 | 12*80 | 12*100 | 12*120 |

| 12*125 | 12*130 | 12*140 | 12*150 | 12*160 | ||||||

| 12.5mm | 12.5*90 | 12.5*100 | 12.5*125 | 12.5*127 | 12.7*101.6 | 12.7*160 | ||||

| 13mm | 13*125 | 13*130 | 13*160 | |||||||

| 14mm | 14*100 | 14*120 | 14.5*80 | |||||||

| 15mm | 15*30 | 15*35 | 15*50 | 15*60 | 15*80 | 15*100 | 15*120 | 15*125 | 15*150 | |

| 16mm | 16*30 | 16*90 | 16*100 | 16*110 | 16*125 | 16*130 | 16*140 | 16*150 | 16*160 | |

| 20mm | 20*76 | 20*100 | 20*120 | 20*130 | ||||||

| Square bar | 19*19 | 30*45 | 15*15 | |||||||

| Round bar | Φ6 | Φ8 | Φ10 | Φ11 | Φ12 | Φ14 | Φ15 | Φ15.6 | Φ16 | Φ18 |

| Φ20 | Φ21 | Φ22 | Φ23 | Φ25 | Φ27 | Φ28 | Φ30 | Φ32 | Φ35 | |

| Φ38 | Φ40 | Φ45 | Φ50 | Φ55 | Φ60 | |||||

| Round angle aluminum bar | |||||||||

| 2mm | R2*20 | R2.5* 50 | |||||||

| 3mm | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | |

| 4mm | R4*25 | R4*30 | R4*35 | R4*40 | R4*50 | R4*60 | R4.1*44.1 | R4.7*151 | |

| 5mm | R5*30 | R5*35 | R5*40 | R5*45 | R5*50 | R5*60 | R5*70 | R5*75 | R5*80 |

| R5*90 | R5*100 | R5*120 | |||||||

| 6mm | R6*40 | R6*50 | R6*60 | R6*70 | R6*80 | R6*100 | R6*120 | R6*140 | R6*160 |

| R6.3*63 | R6.35*76.5 | ||||||||

| 7mm | R7*70 | ||||||||

| 8mm | R8*40 | R8*50 | R8*60 | R8*80 | R8*100 | RS*120 | |||

| 10mm | R10*20 | R10*40 | R10*50 | R10*60 | R10*75 | R10*80 | R10*100 | R10*120 | R10*125 |

| R10*150 | R10*160 | R10*170 | R10.4*25 | ||||||

| 12mm | R12*80 | R12*100 | R12*110 | R12*120 | R12*125 | R12*150 | R12*160 | ||

| 12.5mm | R12.5*80 | R12.5*125 | R12.7*90 | R12.7*127 | |||||

| 13mm | R13*120 | R13*125 | |||||||

| 14mm | R14*100 | R14*120 | R14*150 | ||||||

| 15mm | R15*100 | R15*120 | R15*130 | R15*150 | |||||

| 16mm | R16*150 | R16*160 | |||||||

| 19mm | R19.05*101.6 | R19.05*127 | |||||||

| 20mm | R20*80 | R20*120 | R20*130 | ||||||

| Special-shaped hypotenuse | *4*50 | *5*50 | *5*60 | *6*40 | *6*50 | *6*60 | *6*80 | *8*60 | *8*80 |

| *8*100 | *8*120 | *10*40 | *10*80 | *10*100 | *10*120 | *12*80 | *12*100 | *12*120 | |

| *15*120 | *20*130 | *28*60 | |||||||

Mechanical Properties of Aluminum Bus Conductor and Related Alloys

(The Aluminum Association ; ASTM B 236, B 241, and B 429; and Manufacturer’s Listings)

| Product | Alloy and Temper |

Thickness in Ultimates |

Tensile Strength (ksi) At 20 (68。F) |

Typical Ultimate |

Typical Yield |

Typical(a) Elongation (Percent - in 2 in. Or 4 Dia) |

|

|

Minimum Ultimate |

Minimum Yield |

||||||

|

Extruded rod, bar tube, pipe and shapes |

1350-H111 | All | 8.5 | 3.5 | 35.0 | ||

| 6101-T6 | 0.125-0.500 | 29.0 | 25.0 | 32.0 | 28.0 | 15.0 | |

| 6101-T61 |

0.125-0.749 0.750-1.499 1.500-2.000 |

20.0 18.0 15.0 |

15.0 11.0 8.0 |

||||

|

6101-T63 6101-H111 6101-T64 6101-T65 |

0.125-0.500 0.250-2.000 0.125-1.000 0.125-0.749 |

27.0 12.0 15.0 25.0 |

22.0 8.0 8.0 20.0 |

14.0 | 11.0 | ||

| Extruded pipe(c) |

6061-T6 6063-T6 |

Pipe size 1.0 & over Pipe sizes,all |

38.0 30.0 |

35.0 25.0 |

45.0 35.0 |

40.0 31.0 |

10.0 min 8.0 min |

| Rolled bar | 1350-H12 | 0.125-1.000 | 12.0 | 8.0 | 14.0 | 12.0 | |

| Sawed-plate bar or sheet | 1350-H112 |

0.125-0.499 0.500-1.000 1.001-3.000 |

11.0 10.0 9.0 |

6.0 4.0 3.5 |

10.0min 16.0min 22.0min |

||

|

Rolled sheet (for shearing or forming) |

1350 1350-H12 1350-H14 |

0.020-0.249 |

8.0 12.0 14.0 |

12.0 14.0 16.0 |

4.0 12.0 14.0 |

20-30 min 4-9 min 3-6 min |

|

|

1350-H16 1350-H18 |

0.020-0.125 |

16.0 18.0 |

18.0 | 16.0 |

2-4 min 2-4 min |

||