- CONTACT EMAIL:

- service@signialuminium.com

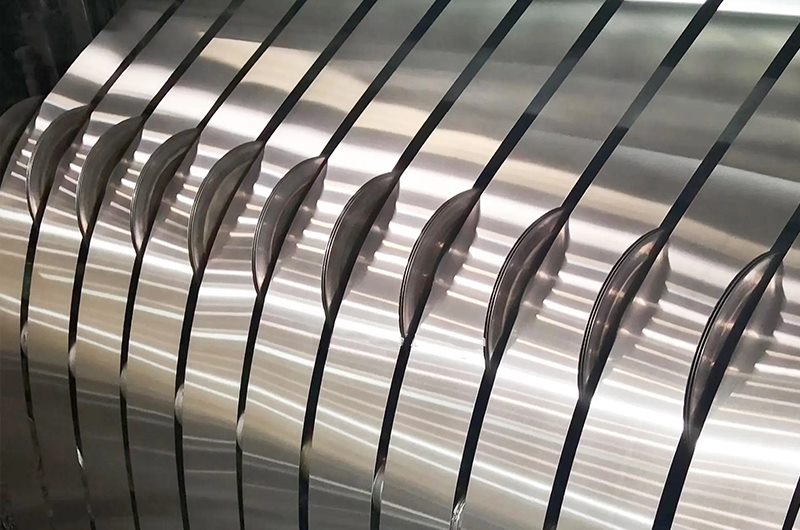

6063 T5 58% IACS aluminum flat bar strip with high-strength conductive, high thermal conductivity is the current computer CPU, VGA and other heat sinks, communication switch heat sinks, etc., mostly using 6063/T5 aluminum alloy material, its main components: Mg 0.49-0.9%, Si0.2~0.6 %, the tensile strength is ^L60MP, the yield strength is 2110MPa, the elongation is 8^8%, the electrical conductivity is 51.5~55% IACS, and the thermal conductivity is 202w/nvk.

The disadvantage of ordinary 6063 is that the content of impurities is not controlled and the range of Mg and Si content is too wide to stabilize the performance. Therefore, the electrical and thermal conductivity of the 6063/T5 aluminum alloy bus bar needs to be further improved. With the rapid development of computers, the requirements for CPU heat dissipation are getting higher and higher, and materials with higher electrical and thermal conductivity are urgently needed to replace the traditional 6063/T5 alloy. Henan chalco aluminum production, which includes the following components by weight: Mg 0.61~0.65%, Si 0.4~0.45%, rare earth elements 0.21~0.3%, B 0.03-0.10%, the balance is AI and unavoidable impurities. Wherein, the rare earth elements are mainly cerium (Ce) and lanthanum (La). The aluminum alloy material also includes: Mn ≤ 0.03%, Fe ≤ 0.12%, V ≤ 0.03%, Cr 0.15%. The above impurities should be reduced as much as possible in the content of the alloy material. 6063 T5 aluminum flat bar strip After testing, the material properties are: tensile strength (t5) 174MPa, yield strength (t5 0.2) 115MPa, elongation (t5) 8.0%, electrical conductivity 58.8 IACS.

6063 T5 58% IACS aluminum flat bar strip The preparation method of aluminum alloy material with high electrical conductivity and thermal conductivity and high strength includes the following steps:

1) add 3~3.5 parts by weight of molybdenum-silicon alloy and 95~97 parts by weight of aluminum first, be heated to 700-800 ℃ of melting, add 1.9~3.3 parts by weight of molybdenum-rare earth alloy and 0.03~0.10 parts by weight of boron , then add 0.63 ~ 0.68 parts by weight of magnesium, add 1.5 ~ 2 parts by weight of refiner refining at 720 ~ 740 ℃ for 15 ~ 20 minutes, then at 680 ~ 710 ℃ after standing for 13 ~ 18 minutes, carry out casting ;

2) Homogenizing treatment and then keeping at 560-580°C for 3.5-4.5 hours, and heating at 180-220°C. C/h cooling rate for cooling. Among them, the silicon content in the aluminum-silicon (Al-Si) alloy is 12-14%. The content of rare earth (Re) in the aluminum-rare earth (Al-Re) alloy is 9-11%. The refiner adopts Al-Ti-C or Al-Ti-B. The use of refiners ensures uniformity of the organizational structure. The refining is carried out by the mixed refining method of liquid nitrogen or 99.99% gas nitrogen and refining agent. The refining agent is 40% cryolite Na3AlF6+30 NaCl+30 KCl. The aluminum alloy material with high electrical and thermal conductivity and high strength of the present invention can be used as the raw material of heat sinks such as computer CPU and VGA, and heat sinks of communication switches.

6063 T5 58% IACS aluminum flat bar strip The performance test data of high electrical and thermal conductivity and high strength aluminum alloy materials are as follows: Tensile strength, yield strength and elongation are tested using "GB/T228-2002 Room temperature tensile test method for metal materials. ", the conductivity detection adopts "YS/T478-200 copper and copper alloy conductivity eddy current detection method" to detect, the performance of the present invention's high electrical conductivity, high-strength aluminum alloy material is: tensile strength (t5b) 172MPa, yield The strength (t50.2) is 113MPa, the elongation (t5) is 8.2%, and the electrical conductivity is 59% IACS. Since the carrier of heat conduction is mainly electrons in the metal, the high electrical and thermal conductivity, high-strength aluminum alloy material of this embodiment includes the following The components in the stated weight percentages: Mg0.65%, Si 0.45%, Ce0.21%, La 0.08%, B0.07%, V 0.012%, Mn 0.016%, Cr 0.015%, Ti 0.013%, Zr 0.02 %, and the rest are Al.

Mobile:86 17344894490

Email:service@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan