Aluminum Busbar

Author:Frank Time:2023-05-05

Aluminum bus bars, with the characteristics of light weight, high conductivity, easy bending and forming, economical use, corrosion resistance, etc., are more and more widely used in the power industry.

Let's take a look at the most commonly used electrical aluminum bus bar type:

Electrical aluminum bus bar

Electrical aluminum bus bar alloy:

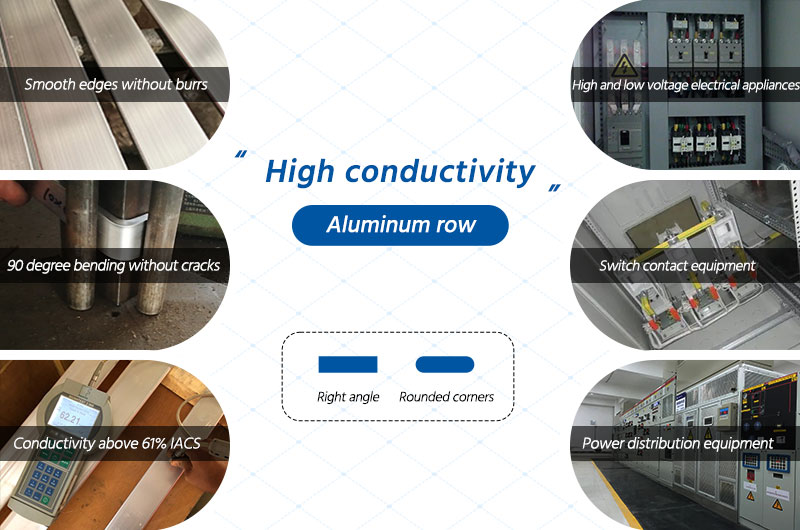

ENAW-1370 /1350 O temper Aluminum bus bar is a commonly used grade in Europe, above 61% IACS, and can be made into rounded and right-angled shapes.

1060 O temper Aluminum bus bar and 1070 O temper Aluminum busbar are commonly used in China, with aluminum content reaching over 99.6%, electrical conductivity over 61% IACS, high plasticity, 90-degree bending, corrosion resistance, and good thermal conductivity. feature.

High conductivity aluminum bus bar

Electrical aluminum flat bar application :

It is suitable for various electrical equipment, high and low voltage electrical appliances, switch contact equipment, power distribution equipment, bus ducts and other electrical engineering, as a electrical bus, electrical equipment, transformer industry, heat dissipation equipment and other industries.

Electrical aluminum bus bar current:

Depending on the bus bar size, aluminum busbars can handle up to 4000A, which is more than enough for many applications.

Manufacturing process of high electrical aluminum bar:

Aluminum bus bar manufacturer put the 1350 1370 1060 1070 aluminum rods for electricians into the continuous extrusion machine, through heating, the aluminum bus bar is continuously extruded, straightened by the stretching machine, sawed according to the required length, and then packaging, etc. If want to know more the specific manufacturing process, please refer to the YouTube link:

https://www.youtube.com/watch?v=Y3-KOTFRI9s

The above models are all pure aluminum bus bars, which cannot be strengthened by heat treatment, so the state is only in O temper.

The disadvantage is that the strength of the material is low. For the electrical parts that need strength support, it is necessary to use aluminum alloy square bars.The following is an introduction to alloy aluminum bars.

High-strength extruded aluminum alloy square bar

6101 T63 T7 Aluminum square bar, is a high-strength conductive material, with a conductivity of 55% IACS guaranteed, good corrosion resistance and weld ability. It is used to process high-strength flat bar conductors. We add rare earth raw materials to the alloy of 6101 to improve it. The conductivity can reach 58% IACS.

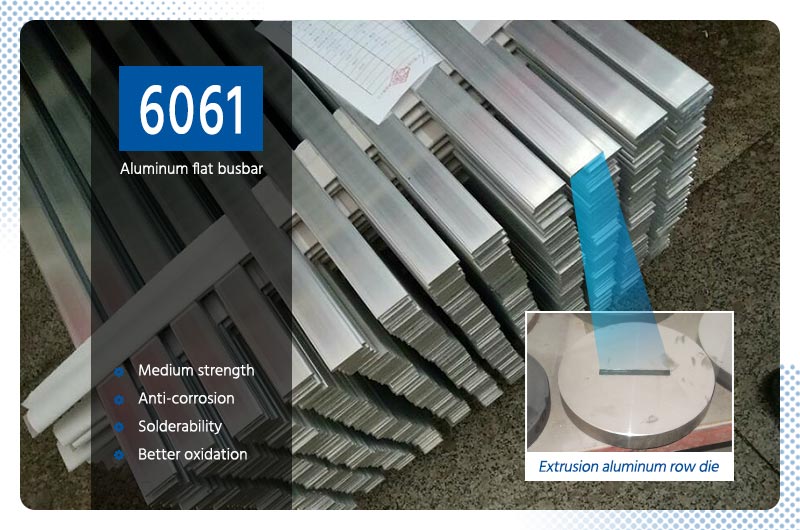

6061 T6 Aluminum flat bus bar, whose main alloying elements are magnesium and silicon, has medium strength, good corrosion resistance, weld ability, and good oxidation effect. It can be used as a low voltage conductive aluminum bar, or as a power link support.

6061 t6 aluminum flat bus bar

6063 T6 Aluminum bus bar is widely used in supports for its good plasticity, moderate heat treatment strength, good welding performance, and gorgeous color after anodizing treatment.

The manufacturing method of the above-mentioned extruded aluminum bars is different from that of conductive aluminum bars. Do the sawing, then wrap etc.

Aluminum flat bus bar size in the market

Thickness: 2mm ~ 250mm

Width: 5mm ~ 300mm

Length: 3000mm/6000mm, 12000mm.

In addition to the aluminum alloy aluminum bars commonly used in the field of industrial power, there are also 6082 T6 aluminum flat bar marine, 7075 T6 rectangular bus bar, 2024 T4 aluminum flat bar etc. aerospace aluminum profiles, etc.

Through the above introduction, you will find that the length of the extruded aluminum bar is limited to 12 meters, which cannot be longer, and cannot meet the customer's demand for ultra-long aluminum bar, please continue to read.

Flat Aluminum roll strip

In order to meet the needs of customers for super long aluminum bus bar, SIGNI has developed a heavy-duty (ultra-long scale) high-performance aluminum alloy flat roll.

High performance rolled aluminum flat bar features:

- With a single piece of heavy weight, it can provide large and heavy coil products without joints

- The structure and properties of the head and tail are uniform and consistent, no extruded coarse grain ring, and no central crack.

- Unlimited batches, abundant product specifications and status, etc.

rolled aluminum bus bar

The main models of high-performance aluminum flat roll coil are 6013 T4 ,widely used in aviation, rail transit, automobile, 3C intelligence and other high-end equipment manufacturing fields, mainly including high-strength and high-conductivity aluminum alloy materials for subway, light rail, and maglev, forging materials for automobiles, construction machinery, aerospace and other fields, aerospace and transportation equipment Connecting materials such as rivets, screws and welding wires for manufacturing, a new generation of 3°C intelligent equipment

Aluminum bus bar packaging and transportation:

We know that aluminum products are not as hard as steel and are easily deformed, especially for thin thickness 1060 1350 1070 temper O aluminium flat bar, is a fully annealed state, which is relatively soft, and its external force Under heavy pressure, it will deform. For example, during transportation, the shaking of the vehicle causes aluminum products to collide with each other. The deformed aluminum products will affect the use.

Therefore, when we want to transport the aluminum bus bar, we must first choose the packaging of the aluminum bus bar to prevent the aluminum bus bar from being oxidized by water vapor during transportation, so in addition to wrapping the surface of the aluminum product with a moisture-proof film , put it in a wooden box.

In the process of transportation, we still need to pay attention to avoid any scratches on the surface, and deliver the goods to the customer in good condition.

Where can buy aluminum bus bar?

How should we choose when we buy aluminum flat bar in the market?

Send the aluminum bus bar specification, and the quantity to the excellent aluminum bar -Henan SIGNI Aluminum,which is very good aluminium bus bar manufacturer in China.

There will be professional international trade business personnel to gave you offer and deliver to you. The usual export ports are Qingdao, Shanghai, Guangzhou, etc., which can be sent to all parts of the world.